Chain driven conveyors

Function

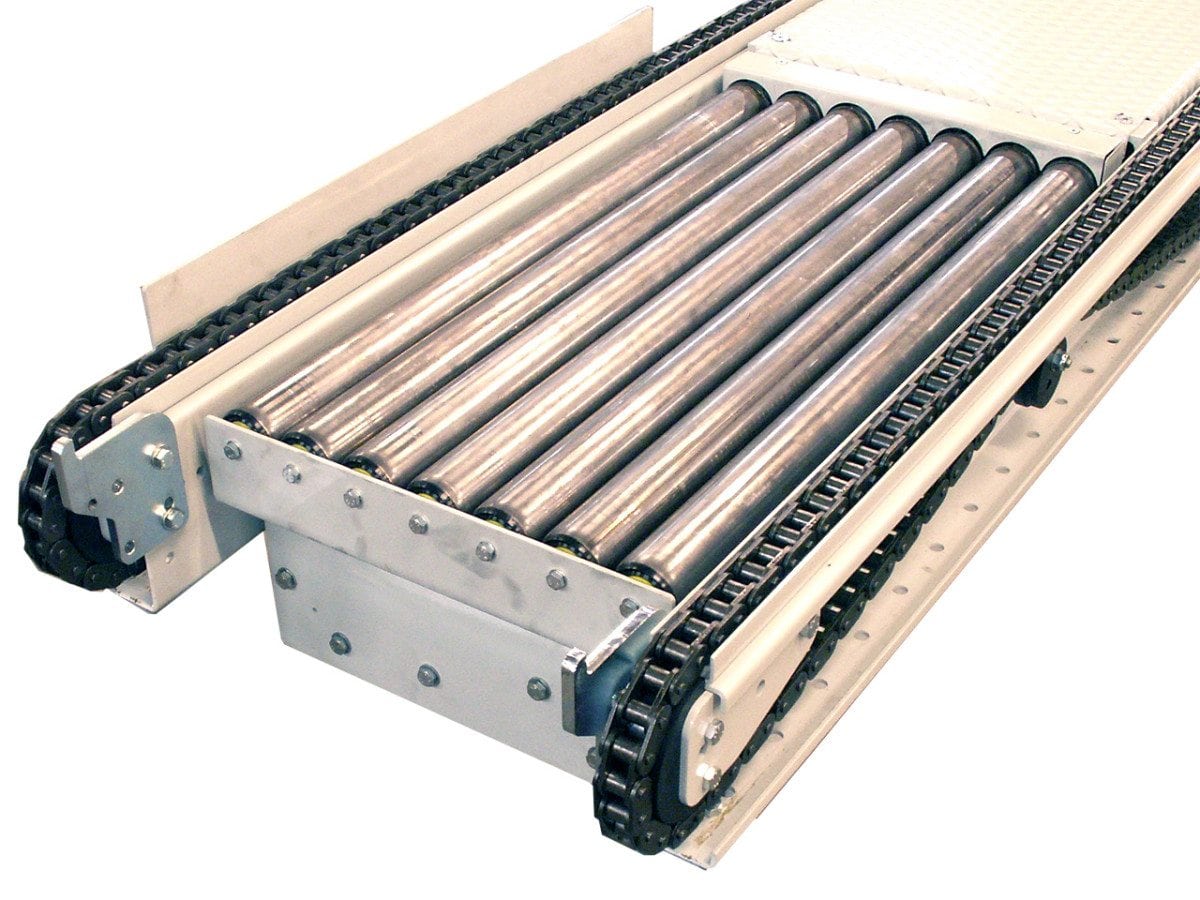

- Conveyor is driven in standard design with chain that tangentially is against rollers cogwheel.

- Rollers exist for both fixated and accumulating drift.

Pros

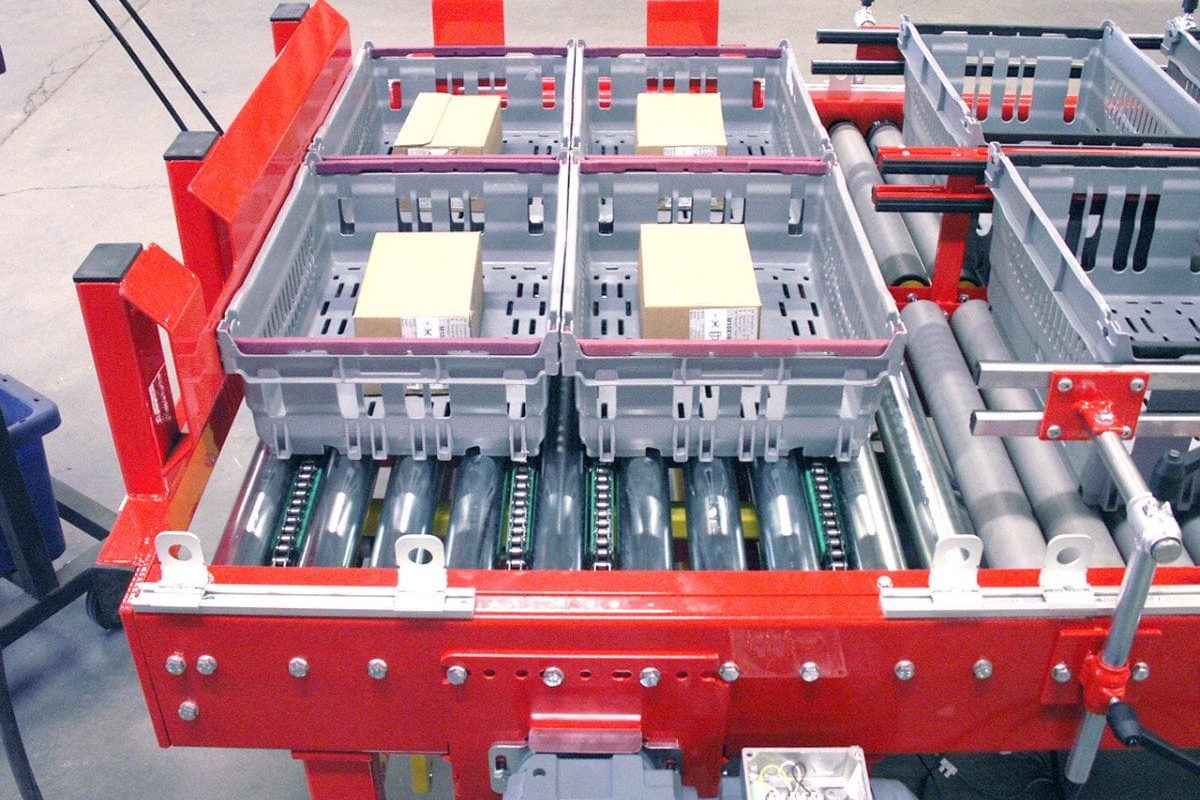

- Specially suitable in environments with demands to withstand heavy conditions.

- High propulsive force when fixated drift is a demand.

- Handles most environments.

- Often used inside the car industry that wish for a stronger build.

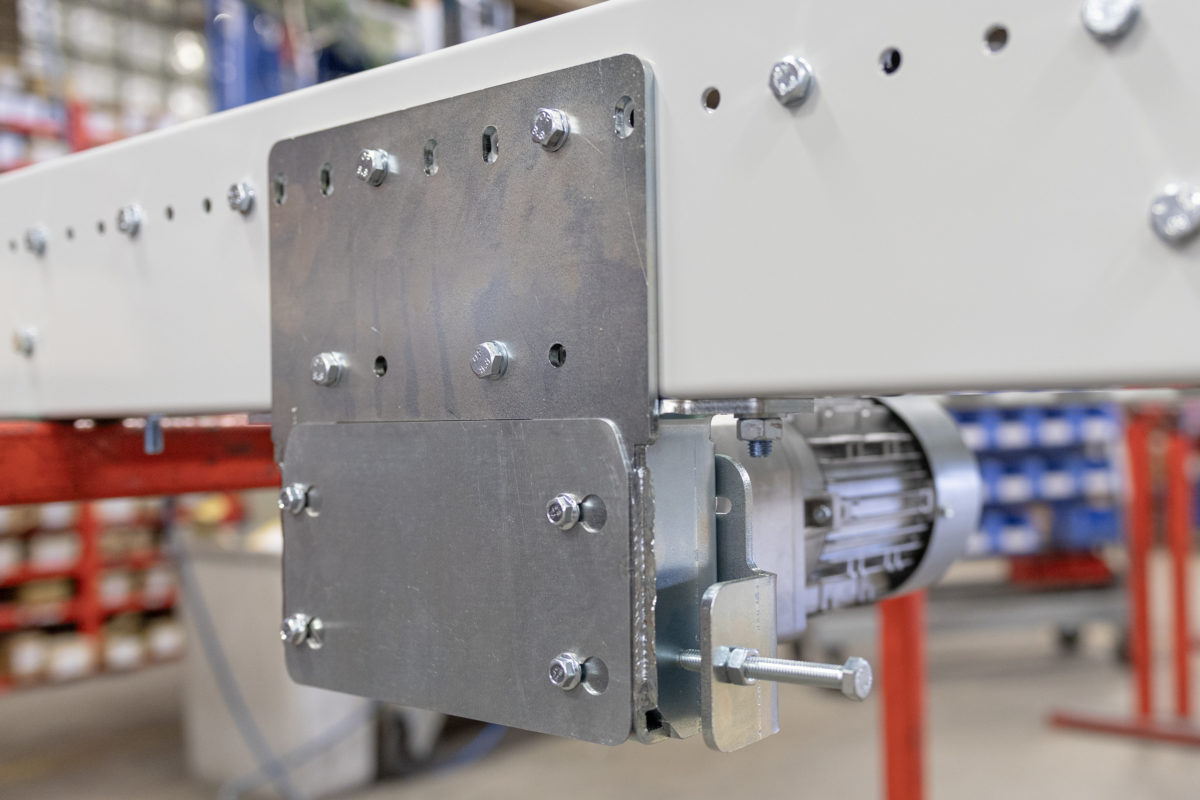

- Low power consumption with under roller driving unit.

Cons

- Transveyors and curves require seperate drive units.

- Cost terms somewhat cheaper than standard pallet conveyors (PA1500).